FEATURES

Factory tested to full regulated pressure to ensure 100% tight shut-off

Standardised actuator attachment flange allows direct and easy attachment of a wide range of Keystone manufactured actuators

One-piece wafer-thin disc stem provides positive disc control and minimal resistance to fluid flow; mirror polished disc surface is ideal for hygienic applications

The primary seal formed by the seat/stem/hub contact surface maintains a complete stem seal at regulated pressures, with the body completely isolated from the fluid.

The secondary stem sealing is self-adjusting and can be used not only at regulated pressure but also in vacuum.

The unique dove-tail shape of the seat eliminates the need for seat bonding, making it easy to replace the seat and preventing tearing.

The flat top and bottom of the seat provides a perfect seal at the hub of the disc, and the polished disc edge provides a perfect seal around the entire disc.

O-ring moulded into the seat provides a positive flange seal and eliminates the need for gaskets between the flanges.

The upper bushing absorbs side loads and the self-adjusting packing provides a bi-directional seal, allowing for use in vacuum.

GENERAL APPLICATION

Ideal valves for the food and beverage industry and available in a variety of material configurations for use in the chemical and petrochemical industries.

Seat and disc can be rubber lined for use as a process valve.

Available in Pulp & Paper, Dry Service, Control Valve, etc.

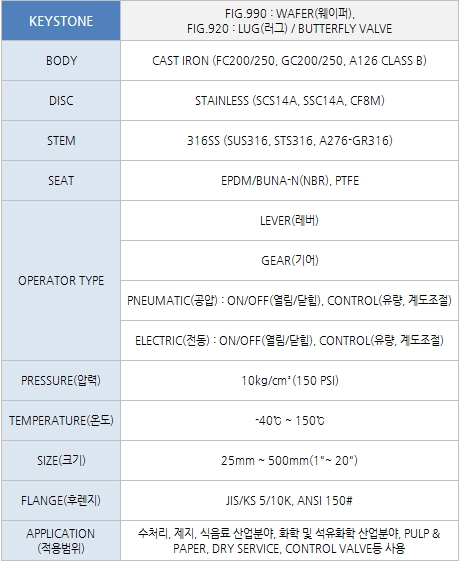

TECHNICAL DATA

Pressure: 10kg/cm2 (150 psi)

Temperature: -40℃ to 150℃ (-40℉ to 248℉)

Size : 25mm to 500mm (1"to 20")

Flange Application : JIS/KS 5K/10K ANSI 150

Please consult the factory for other flange accommodation

상품요약정보

-

제품소재상세설명페이지 참고

-

색상상세설명페이지 참고

-

치수상세설명페이지 참고

-

제조자상세설명페이지 참고

-

세탁방법 및 취급시 주의사항상세설명페이지 참고

-

제조연월상세설명페이지 참고

-

품질보증기준상세설명페이지 참고

-

A/S 책임자와 전화번호상세설명페이지 참고

배송정보

교환/반품

문의 0

문의하기

번호

제목

이름

답변

- 등록된 문의가 없습니다.